KSE Process Technology

Partner in het optimaliseren van productieprocessen

De toenemende complexiteit vormt de grootste uitdaging voor diervoederfabrikanten; meer recepten, een groeiend aantal ingrediënten, moeilijk te doseren bijstortingen en hogere kwaliteitsnormen dragen allemaal bij aan deze trend.

Al meer dan 50 jaar levert KSE toekomstbestendige oplossingen om deze trend voor te blijven, en wel in de vorm van modulaire machines en slimme software die perfect op elkaar aansluiten. We creëren flexibele verwerkingsoplossingen die een responsief productieproces mogelijk maken. Automatisering, nauwkeurigheid en contaminatiecontrole vormen de basis van onze toekomstbestendige innovaties. Ons doel is niet alleen om het productieproces te verbeteren, maar ook om een belangrijke bijdrage te leveren aan het vergroten van marges en het behalen van doelstellingen. Voor fabrikanten die echt de volgende stap willen maken.

Samen creëren we oplossingen met de beste resultaten.

Systemen

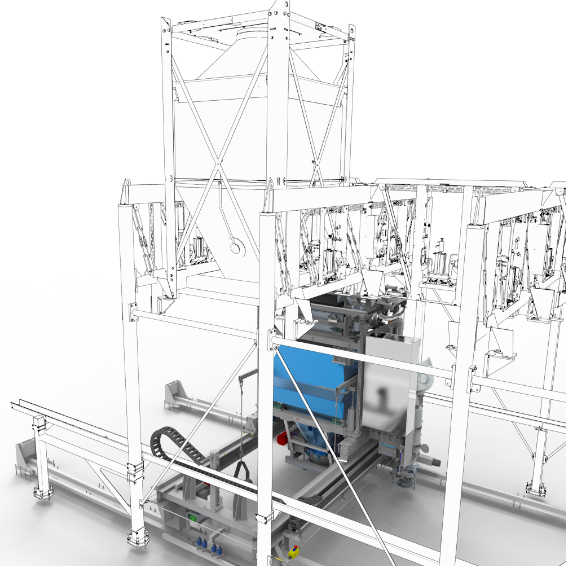

ALFRA: Doseren, wegen & intern transport

ALFRA doseer- en weegsystemen zijn gemaakt om snel, nauwkeurig en betrouwbaar te zijn. Onze engineers ontwerpen oplossingen die flexibiliteit bieden aan uw fabriek met een hoge mate van automatisering en contaminatiecontrole.

Automatisering

PROMAS ST: Toekomstbestendige automatisering

PROMAS ST is ontwikkeld voor het automatiseren van complexe diervoederproductieprocessen. De modulaire software stelt klanten in staat om verschillende automatiseringsniveaus te kiezen en de functionaliteiten te selecteren die passen bij hun huidige behoeften.

Projecten & Consultancy

Van concept tot fabriek

In onze Business Unit Projecten & Consultancy ontwerpen en ontwikkelen wij uitgebreide procesoplossingen voor uw (toekomstige) fabriek. Onze datagedreven aanpak zorgt ervoor dat we oplossingen ontwikkelen en leveren met een voorspelbare performance, die uw business case bij elke stap ondersteunen.

Industrieën

Gespecialiseerd in diervoeder

Wij beschikken over een sterke expertise in de veevoeder- en petfoodproductiesector. Dankzij meer dan 50 jaar ervaring in deze branches zijn wij uitgegroeid tot specialist in het optimaliseren van het productieproces van onze klanten met systemen en slimme software van wereldklasse.

Onze klanten

Benieuwd naar de mogelijkheden?

Laat het ons weten

Of u nu een vraag hebt over opties, functies, prijzen, een demo nodig hebt, of iets anders, ons team staat steeds voor u klaar.

Neem contact op